In the early 20th century, during the second industrial revolution and electrification of industrial processes, Sir Henry Bessemer invented a technique that allowed the mass production of steel, faster production and decreased labour requirements. Previously, steel was very expensive to produce, and, as such, was exclusively used in expensive small items. The technique, which marked the revolution in modern steelmaking, was named after its founder — the Bessemer process. Then came the third industrial revolution with automated processes and tasks for production workers with the use of IT technology.

Now, Industry 4.0 is under way. A number of remarkable technologies are converging: smart machines, three-dimensional printing, enhanced automation and interconnectivity. For the first time, machines have become autonomous business entities capable of working without human assistance, constantly producing and exchanging an astonishing amount of data.

The steel industry embraced some of the finest breakthroughs of Industry 4.0, but not in all areas. In the era before IT or computers, data was gathered using paper-based forms. These data were then processed, filed away and retrieved when necessary. While this sounds like ancient history, the fact is that the idea of manual workflow tasks in the steel sector persists. One of the best illustrations of this concept is paper-based mill test certificates (MTC).

S1SEVEN has built a platform that addresses these issues. In the series of blog posts, we’ll explain the technology behind it and how we assign metals with a tamper-proof digital identity, helping manufacturers to decommoditise products on their road to Industry 4.0.

What to do with all that paper?

A mill test certificate is a bridge between the manufacturer and buyer of steel products. These paper-based certificates include all specifications of the steel product, such as its dimensions, chemical composition and mechanical properties. In Europe, the EN10204 defines the type of certificate, and the EN10168 defines sections for the structure of steel mill certificates. The definitions for most sections are basically non-structured text fields that offer quite a freedom of interpretation. Consequently, various manufacturers provide the relevant information in different ways and fields.

Today, producers of steel create mill certificates by:

1. Printing, signing and scanning a document and

2. Sending it in the form of a PDF document to their buyers via email

Needless to say, this process is inherently insecure and inefficient. First, scanned documents and PDFs are hard to process electronically. As a result, extracting only essential information is done manually in various steps of the value chain. Second, a printed paper with data can go just about anywhere, anytime and with anyone. Even keeping it scanned in PDF form can’t be an ideal solution since these data, once obtained, can be easily modified.

According to the Steel Alliance Against Counterfeiting (SAAC), 53% of suppliers faced counterfeit steel products. This ranges from faked origin to modified test results or even reselling used steel products after refurbishment. Such practices raise not only reputational and legal risks but also health, safety and environmental concerns. For instance, Sapa Profiles Inc., an Oregon-based aluminium extrusion manufacturer, admitted to altering test results and providing false certificates to NASA. According to the space agency, the extrusions used in a key component for the payload delivery system resulted in more than $700 million in losses during two failed satellite launch missions.

Then, in 2017, it was revealed that Kobe Steel, a Japanese steel manufacturer, had issued false inspection certificates stating that their products had met customer manufacturing specifications. Improperly certified metals within products, such as aluminium castings, forgings, flat-rolled items, copper strips and tubes, had been shipped to 200 companies. These companies included industry giants such as Toyota Motor Corp, Central Japan Railway and Mitsubishi Heavy Industries.

Once such an event happens, the manufacturer is faced with the responsibility of detecting and replacing the affected components of the system. With paper-based certificates, this means shuffling through thousands of documents and complex supply chains to track deficiencies.

Converting from paper to electronic certificates

S1SEVEN has developed a blockchain-based certificate validation platform, en10204.io, that offers easy entry into the digitalisation of mill certificates and their quality data. We developed a notarization engine that doesn’t abolish the PDFs but provides JSON on top. The data format, which is kept close to the existing EN 10168 standard, allows for optimal processing by both machines and humans.

Here is how the process works:

1. Data of the (current) certificates are exported from the QM system into a JSON document.

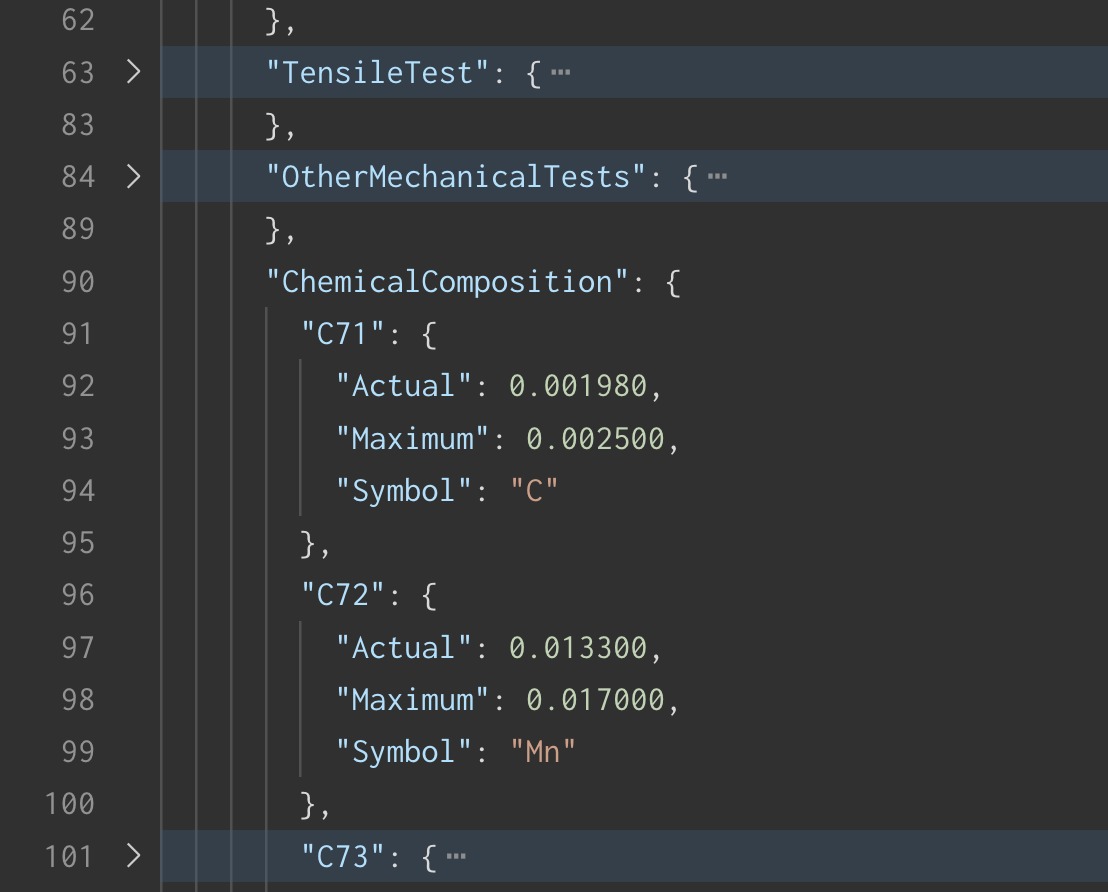

Detail of steel mill certificate JSON

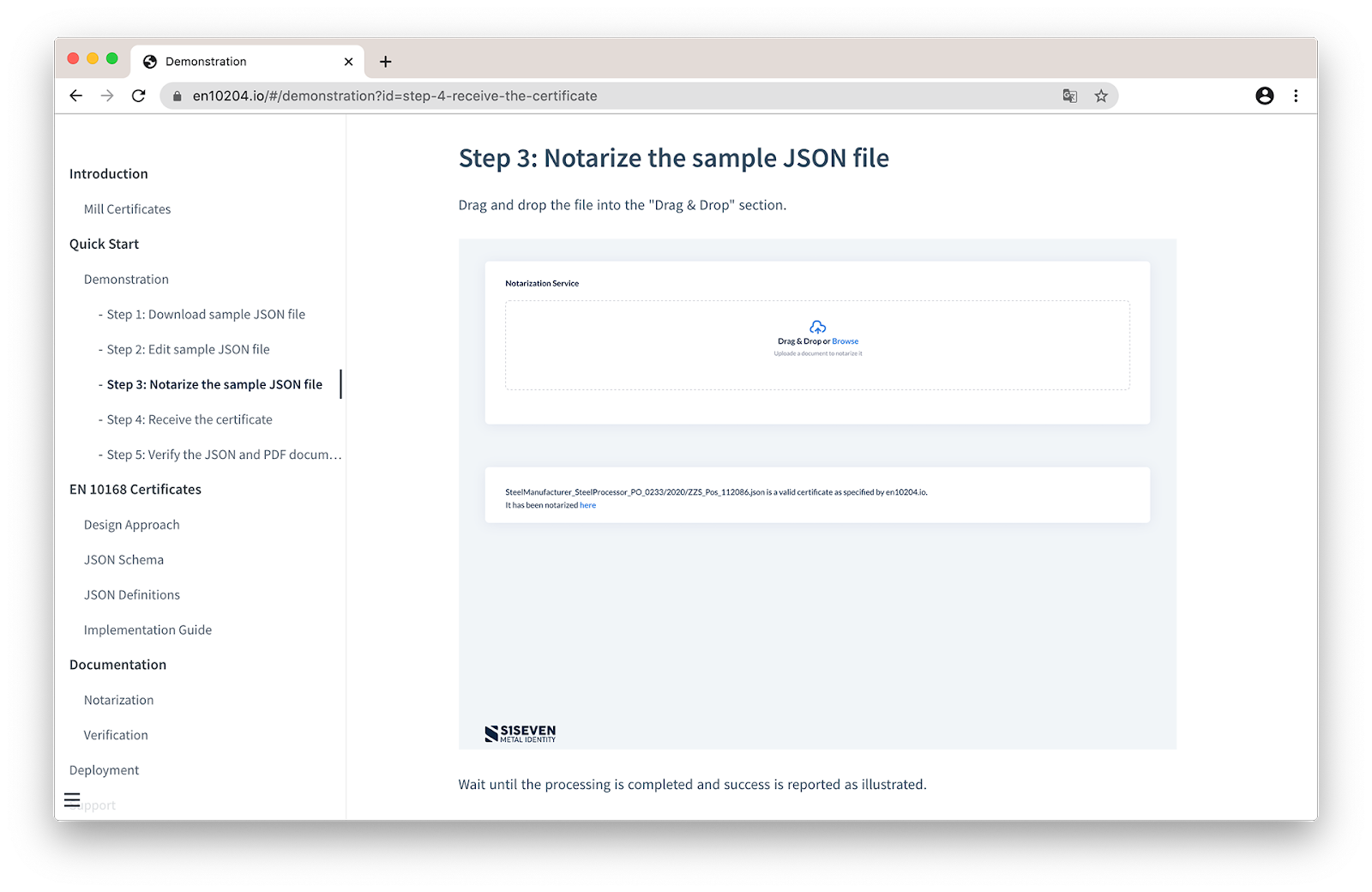

2. This document is then sent to the en10204.io notarisation service via simple REST API.

3. The service validates the document against a JSON Schema to reduce potential structural and data format errors.

4. A unique digital fingerprint — hash — is calculated from the document and notarised on the blockchain.

5. A PDF document is rendered from the JSON document. The hash of the PDF document is calculated and notarised on the blockchain as well.

6. Next, an HTML document is rendered from the JSON document. All three documents — JSON, PDF and HTML — are finally sent to the receiver of the mill certificate.

Each of these three documents has a different purpose:

- HTML allows easy search in mailboxes and displays the data in a way that is comprehensible for humans.

- PDF can be archived in the document management system, also in a way that is comprehensible for humans.

- JSON can be processed by systems, such as MIS, ERP, Warehouse and various processing equipment.

However, since these documents exist in a form of pure text, they can be easily tampered with (especially a JSON document). This puts a challenge in front of the initial receiver to ensure that the provided documents are authentic.

And that is where blockchain, with its immutable nature, can save the day. The notarisation on the blockchain provides the foundation to detect manipulations. Any modification of a JSON or PDF document will result in a change of the digital fingerprint (hash).

Try it yourself at

As the mathematical concept of hash guarantees that there are no two documents with the same fingerprint, detecting any modification is easy. By calculating the hash of the document, we can query the blockchain via an REST API to check if a certain value entry exists:

- If the value exists, the document wasn’t modified.

- If the value doesn’t exist, the document was modified.

Final words

S1SEVEN would love to invite producers of mill certificates to test and use the en10204.io platform. We share all information as open source and see this as a starting point for interaction to improve the format and functionality.

If you want to find out more about S1SEVEN’s areas of work, please visit www.s1seven.com

Hannes Stiebitzhofer

Hannes Stiebitzhofer